S-P-0017018

Hatko Ses BariyerleriRECYCLED RUBBER SOUND BARRIER - NB2

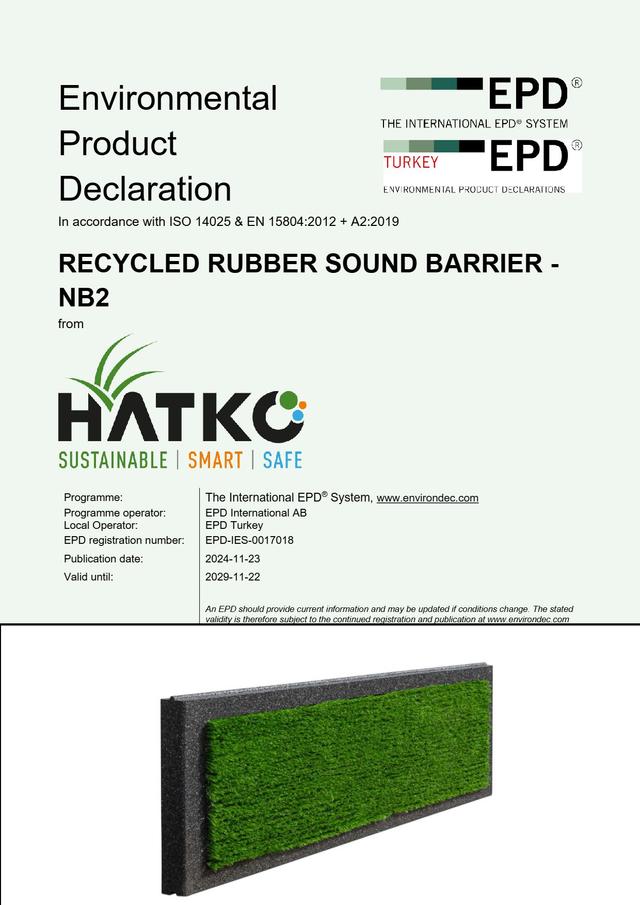

In the sound barrier production plant, the

process starts with aggregating granulated rubber, reinforcement, and

chemicals. This process takes place with a mixing machine.

The raw materials and a desirable quantity

of water are placed into this mixing machine and mixed until the it reaches the

required consistency.

After the mixture is poured into a press

machine that consumes only electricity then the pressing process is applied. As

a result of this pressing process, the mixture becomes solid, and the sound

barrier is created. When it cools down, synthetic turf is stapled onto the

sound barrier in a square shape. The reason for this process is that the sound

barrier looks visually aesthetic.

After the visual

process is completed, the product is ultimately ready and packaged to be

delivered to the customer.

CPC: 36210

ISO 14025 & EN 15804:2012 + A2:2019

Gallery

Registration & Validity

COMPANY INFORMATION

Hatko Ses Bariyerleri

Founded in 1985, Hatko shows activity in construction, synthetic turf, livestock and acoustic sound barriers. Currently has been exporting to all continents of the world and continues to export to 100 countries.

Founded in 1985, Hatko shows activity in construction, synthetic turf, livestock and acoustic sound barriers. Currently has been exporting to all continents of the world and continues to export to 100 countries.

Contact

Merkez Mah. Akar Cad. iTower Kat: 3 No: 11, 34384 Şişli – Bomonti / İSTANBUL

hatkokaucuk.com

See NowHatko started to break into the recycling sector in 2010 and is the largest company in Turkey and the Middle East with its annual production capacity of 20 thousand tons, which recycles end-of-life tires. Hatko meets its own needs by using it as filling material for the turf it produces, the subfloor of athletics tracks, cow mats and acoustic sound barriers.

Founded in 1985, Hatko shows activity in construction, synthetic turf, livestock and acoustic sound barriers. Currently has been exporting to all continents of the world and continues to export to 100 countries.

Hatko Kauçuk A.Ş has branches and manufacturing facilities in Istanbul, Ankara, İskenderun, İzmir, Antakya and Osmaniye. Hatko started to break into the recycling sector in 2010 and is the largest company in Turkey and the Middle East with its annual production capacity of 20 thousand tons, which recycles end-of-life tires. Hatko meets its own needs by using it as filling material for the turf it produces, the subfloor of athletics tracks, cow mats and acoustic sound barriers.