S-P-0017884

Sönmez Çimento Yapı ve Madencilik San. Tic. A.Ş.CEM I 42,5 R

The cement production process

begins with the extraction of primary raw materials, primarily limestone and

clay. These materials, along with marl and other naturally occurring resources,

are extracted from quarries and transported to the production facility. In

addition to these primary raw materials, other materials such as iron ore,

bauxite, and pumice may also be added to achieve the desired chemical

composition for the final product. Portland cement clinker is manufactured from

limestone, marl, clay, and iron ore/bauxite as corrector.

The raw materials are initially

crushed using crushers to reduce them to smaller sizes. Once crushed, the raw

mix is ground in a raw mill and called farin.

Farin is subsequently burned in a

rotary kiln at a temperature around 1.450°C. Partial fusion occurs, and nodules

of clinker are produced. During the burning process, the raw materials will

undergo complex chemical reactions and will eventually leave the kiln as cement

clinker. The clinker typically has a composition in the region of 67% CaO, 22%

SiO2, 5% Al2O3, 3% Fe2O3, and 3% other components, and normally contains four

major phases, called alite, belite, aluminate, and ferrite. Several other

phases, such as alkali sulfates and calcium oxide, are normally present in

minor amounts. The clinker produced in the kiln is cooled and stored in clinker

silos.

For the final production of cement,

the clinker is ground in the cement mill, where various additives are mixed in

to modify the properties of the cement. These additives may include substances

such as gypsum or fly ash, which are incorporated in varying proportions

depending on the specific type of cement being produced. The final product -

cement - is obtained by grinding the clinker to a fine powder, in a cement mill

together with minor/major additives and 3-4% of gypsum. The gypsum is a

necessary additive in order to retard the setting time of cement. This stage

allows for the adjustment of the cement's characteristics, such as setting

time, strength, and durability, according to the requirements of different

applications.

Finally, the finished cement is

stored in storage silos before being either packaged for shipment or

transported directly to construction sites or distribution points for use in

various construction projects.

CEM I 42,5R is commonly used in

various types of reinforced concrete buildings. These types of cement are

suitable for high-strength concrete applications, as well as for reinforced

concrete structures with thin sections. They are also ideal for buildings with

specialized requirements, high-rise reinforced concrete buildings, and

strengthening works for existing structures. These cements are extensively used

in the construction of bridges, viaducts, silos, and water tanks. Additionally,

they are used in road pavements, runways, and buildings constructed using slip

formwork or tunnel formwork systems. Another significant application is in

early-strength reinforced concrete production.

In industrial production, these

cements are used in the production of gas concrete, tile and ceramic adhesives,

and prefabricated, prestressed concrete elements. They are also utilized in the

manufacturing of railroad prestressed concrete ties, prefabricated reinforced

concrete building components, and for the production of concrete poles for

lighting and energy transmission lines. Other industrial applications include

the production of concrete pipes and curbstones.

CPC: 37440

14025:2006 and EN 15804:2012+A2:2019/AC:2021

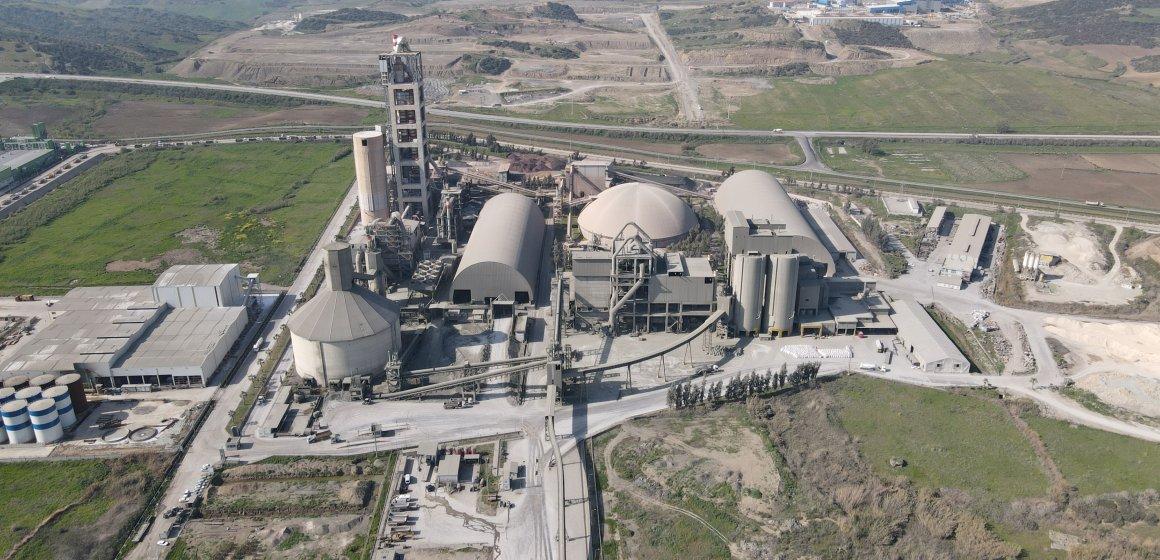

Gallery

Registration & Validity

COMPANY INFORMATION

Sönmez Çimento Yapı ve Madencilik San. Tic. A.Ş.

Sönmez Cement, which was founded in December 2012 in partnership with Sönmez Holding, Kutlucan Holding and Türkün Holding, started production in Adana Yumurtalık Free Zone in September 2014 and made it’s first export in October 2014. Sönmez Cement, which employs more than 400 people with it’s 470-acre port and operating area in Iskenderun Bay, is the first and only cement factory established in free zones in Türkiye and also the largest chimney industrial facility.

With a production capacity of 2 million tons/year of clinker and 2.16 million tons/year of cement, Sönmez Cement exports more than 90% of it’s production. Designed in accordance with current environmental legislation with new generation dedusting systems, Sönmez Cement continues to be environmentally friendly with the use of alternative raw materials and by-products.

Contact

Adana Yumurtalık Serbest Bölgesi Sarımazı SB Mh. 2. Bulvar 5. Cadde No:5/01 Ceyhan / Adana / TÜRKİYE

0322 634 21 70https://www.sonmezcimento.com.tr/

See NowSönmez Cement, which completed it’s port operation in November 2017 and started loading clinkers and cement from it’s own port, opened the port business to third parties in February 2021 in order to support the country’s exports.

Sönmez Cement, which was

founded in December 2012 in partnership with Sönmez Holding, Kutlucan Holding

and Türkün Holding, started production in Adana Yumurtalık Free Zone in

September 2014 and made it’s first export in October 2014.

Sönmez Cement, which

employs more than 400 people with it’s 470-acre port and operating area in

Iskenderun Bay, is the first and only cement factory established in free zones

in Türkiye and also the largest chimney industrial facility.

With a production capacity of 2

million tons/year of clinker and 2.16 million tons/year of cement, Sönmez

Cement exports more than 90% of it’s production.

Designed in accordance with

current environmental legislation with new generation dedusting systems, Sönmez

Cement continues to be environmentally friendly with the use of

alternative raw materials and by-products.

Sönmez Cement, which

completed it’s port operation in November 2017 and started loading clinkers and

cement from it’s own port, opened the port business to third parties in

February 2021 in order to support the country’s exports.