S-P-04137

Tosyalı ÇelikProfile

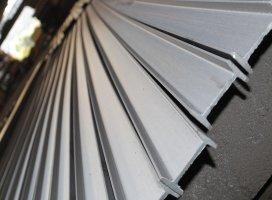

Hot rolled profile products production facilities were established in Hatay. The facility provides services in a total area of 17,667 m2 with 13,000 m2 closed area. The annual production capacity is 550,000 tons/year. In this facility UPN profile, IPN profile and IPE profiles are produced.

Intended Use of Product

Profile is used especially in energy transmission line, as well as all steel constructions, machinery manufacturing industries, and various structures.

Production

In the profile production plant, firstly, 130x130 mm and 150x150 mm billet are heated in the furnace up to 1,250 °C. Then it passes through the rotating rollers and is formed by hot forming. These materials, especially made by hot shaping, gain a more durable structure due to the homogeneous reduction of grain sizes. Electricity, water, and natural gas are consumed in these stages.

End of the processes the profile is ready and packaged to be delivered to the customer.

CPC: N/A

ISO 14025 and EN 15804:2012+A2:2019

Gallery

Registration & Validity

COMPANY INFORMATION

Tosyalı Çelik

Investments in our facilities started in 1993 and the production started in 1994. In 1995, angle iron was added to the production matrices. With the investment in 2001, the 2nd Rolling Mill was established and its current capacity doubled. And IPN-UPN-IPE profile is added to the product group.

Tosyalı Demir Çelik rolling mill facilities in İskenderun are established on a total area of 17,667 m2 with 13,000 m2 closed area. The annual production capacity is 550,000 tons / year.

Contact

Organize Sanayi Bolgesi Sarıseki İskenderun / HATAY

https://www.tosyalidemircelik.com.tr

See NowFor all of our products, cast-based tensile tests, chemical tests, bending tests and charpy impact tests are performed in our own laboratories. Follow-up and control of all quality system documentation is performed by using the QDMS system. All information about our products is recorded in our SAP system database. Especially with the barcode system on the product package labels, traceability is ensured until the product reaches the customer.

Investments in our facilities started in 1993 and the production started in 1994. In 1995, angle iron was added to the production matrices. With the investment in 2001, the 2nd Rolling Mill was established and its current capacity doubled. And IPN-UPN-IPE profile is added to the product group. Tosyalı Demir Çelik rolling mill facilities in İskenderun are established on a total area of 17,667 m2 with 13,000 m2 closed area. The annual production capacity is 550,000 tons / year.

The following standard and special sizes are produced in the following groups in Tosyalı Demir Çelik facilities:

• From 30 mm to 120 mm / 2.8 mm to 13 mm wall thickness in the angle iron group,

• From 50 mm to 160 mm in the UPN profile group,

• From 80 mm to 160 mm in the IPN profile group,

• From 80 mm to 160 mm in the IPE profile group.

For all of our products, cast-based tensile tests, chemical tests, bending tests and charpy impact tests are performed in our own laboratories.

Follow-up and control of all quality system documentation is performed by using the QDMS system. All information about our products is recorded in our SAP system database. Especially with the barcode system on the product package labels, traceability is ensured until the product reaches the customer.